For which applications does RX.control offer added value?

Whenever an application has a complexity that suggests an architecture with multiple processes (or threads) and asks for more than a PLC-based solution - like it is more and more common in Industry 4.0 applications - RX.control offers a rich platform on which such a system can be efficiently deployed. A solution with integration of a PLC, often a soft PLC, for parts with simpler I/O logic is certainly still possible and useful (see Connectivity / Device Integration).

Such distributed applications, made from multiple processes that communicate with each other and share data are a field-tested solution, for example, for the following applications:

- Systems that control multiple devices, sensors, drives, etc. in parallel, e.g. For industrial control systems, robots, telescopes or medical devices.

- Systems implementing a data processing chain, e.g. camera controllers (with filter wheel, focuser, etc.) with onboard image processing, data storage and presentation or transmission.

- Systems that implement services for multiple clients in parallel.

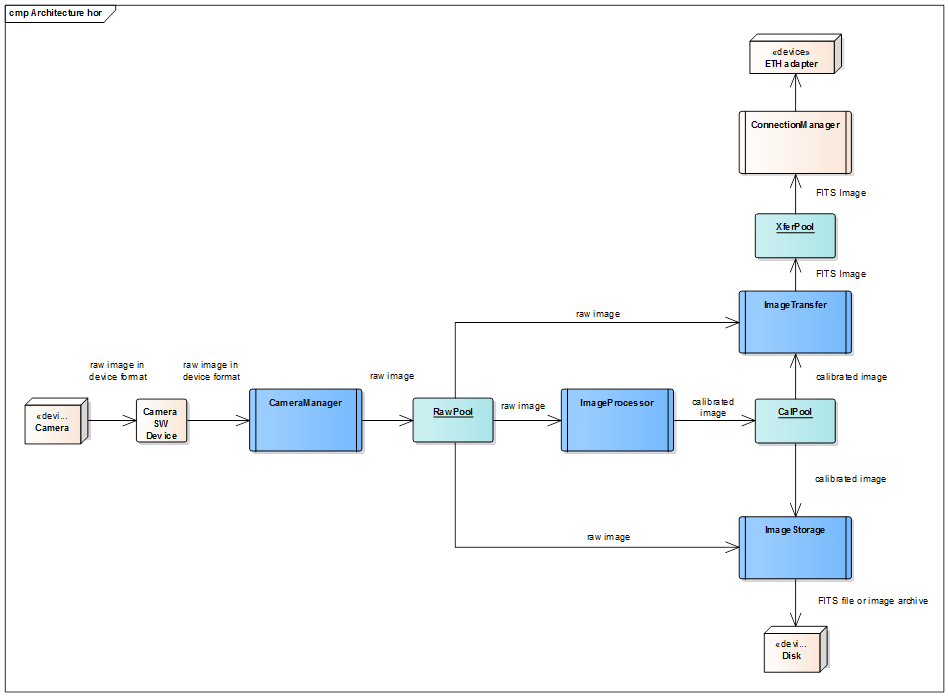

The following diagram shows an architecture for the application "processing chain", here the example of a camera control application with onboard image processing.

The added value of RX.control is that the development time and costs of such systems are reduced by the effort to build the necessary platform itself. Developers can focus on the core tasks of their application rather than implement basic functionality.